Keg Tracking vs Pour Tracking: What Breweries Actually Need (And Why Most Systems Fail)

The modern draught beer world is getting a lot more data‑driven. Breweries want visibility into their keg fleet, bars want accurate pour data, and distributors want fewer lost assets. As a result, terms like keg tracking, keg monitoring, and pour tracking are used everywhere - often interchangeably.

But they are not the same thing.

A lot of breweries invest in the wrong technology because they misunderstand what problem they are trying to solve. The result? Expensive hardware, disconnected software, and systems that never deliver real ROI.

In this article, we’ll break down the difference between keg tracking and pour tracking, explain where monitoring fits in, and outline what breweries actually need to build a smart draught ecosystem.

What Is Keg Tracking?

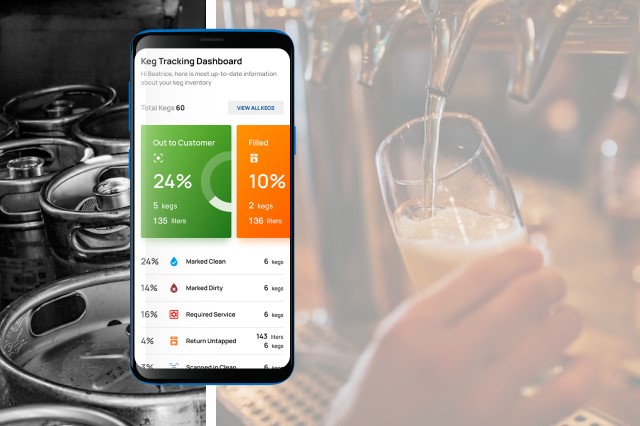

Keg tracking focuses on the keg as an asset. A comprehensive keg tracking system answers one simple question: Where is my keg right now - and what stage of the lifecycle is it in?

Tracking systems typically use:

- QR codes or barcodes

- RFID tags

- GPS or IoT trackers

- Mobile scanning apps

A keg status monitoring platform helps breweries:

- Reduce lost or stolen kegs

- Monitor fleet utilization

- Track deliveries and returns

- Understand dwell time at customer locations

For breweries managing thousands of kegs across distributors, tracking provides logistical control that spreadsheets simply can’t deliver.

But tracking alone doesn’t tell you how much beer has been poured or whether that keg is performing well at the bar.

What Is Pour Tracking?

Pour tracking measures what happens at the tap - not the keg. These systems use flow meters or smart tap sensors to measure liquid moving through the draught line. Instead of tracking assets, they track consumption.

Pour tracking answers questions like:

- How many ounces were poured today?

- Which taps generate the most revenue?

- Is staff over-pouring or wasting product?

- How much beer remains based on actual dispensing?

Typical hardware includes inline flow meters, smart faucets, POS integrations, and analytics dashboards. Bars and restaurants use pour tracking primarily for inventory control and loss prevention, while breweries use it to understand real-world sales velocity through detailed brewery pour analytics.

But here’s the key limitation: pour tracking doesn’t know where the keg came from or where it goes after it’s empty.

Where Keg Monitoring Fits In

Between tracking and pour analytics sits a third layer: keg monitoring. Monitoring uses IoT sensors to capture environmental or operational data such as:

- Temperature exposure

- Motion or transport events

- Pressure or level data

- Usage patterns

Unlike tracking, which focuses on location, monitoring focuses on condition and performance. It gives breweries insight into quality control and logistics efficiency. In modern draught technology, monitoring is often combined with tracking to create “smart keg” ecosystems.

Why Most Systems Fail

Despite the availability of advanced technology, many keg tracking and pour tracking deployments fail to deliver value. Here are the most common reasons:

1. Solving the Wrong Problem

A brewery worried about lost kegs may invest in pour tracking hardware - which doesn’t solve asset loss. Likewise, a bar focused on waste reduction might buy tracking software that never touches the tap. Without defining the real goal - logistics vs. analytics - systems quickly become underused.

2. Hardware Without Software Strategy

Many vendors sell devices instead of platforms. Breweries end up with:

- RFID data in one system

- Flow meter data in another

- Manual spreadsheets tying everything together

The lack of a unified dashboard leads to data silos and poor adoption.

3. Overcomplicated Installations

If the solution requires constant manual scanning, battery swaps, or complex calibration, staff simply stop using it. Successful systems are automated, low maintenance, and integrated into existing workflows.

4. No Lifecycle Visibility

The biggest gap in most deployments is failing to connect: Fill → Ship → Tap → Pour → Return → Refill. Tracking sees logistics. Pour tracking sees sales. Monitoring sees conditions. But when these layers don’t communicate, breweries never get a full picture of keg performance.

What Breweries Actually Need

The industry trend is moving toward hybrid platforms that combine keg tracking systems and brewery pour analytics into one seamless ecosystem. A modern draught data strategy should include:

- Asset tracking to manage the keg fleet

- Monitoring sensors for operational insights

- Pour tracking for real-world consumption data

- Cloud analytics that connect all three layers

Instead of choosing one technology, successful breweries focus on building a connected data environment.

Keg Tracking vs Pour Tracking: Quick Comparison

| Feature | Keg Tracking | Pour Tracking |

|---|---|---|

| Primary Focus | Asset location | Dispensing analytics |

| Tracks pours | No | Yes |

| Tracks keg movement | Yes | No |

| Hardware Examples | RFID, QR, GPS | Flow meters, smart taps |

| Main Users | Breweries, distributors | Bars, taprooms |

The Future of Draught Technology

As breweries scale and margins tighten, visibility across the entire keg lifecycle becomes essential. The next generation of draught systems will not treat tracking and pouring as separate categories - they will merge logistics data with real-time consumption analytics.

Breweries that invest strategically in integrated platforms will reduce keg loss, improve forecasting, and make smarter decisions about production and distribution. Those that deploy isolated tools without a clear objective risk building expensive systems that nobody uses.

FAQ: Keg Tracking vs Pour Tracking

What's the difference between keg tracking and pour tracking?

Keg tracking follows asset location and lifecycle (fills, returns, losses). Pour tracking measures tap pours via flow meters for consumption and waste—no keg movement data.

Which is better for breweries: keg tracking or pour tracking?

Breweries need keg tracking first for fleet control and loss reduction. Add pour analytics for sales insights - hybrids like KegChek combine both without silos.

How does keg monitoring fit with tracking and pouring?

Monitoring adds IoT data (temp, pressure) to tracking's location info. Pouring handles taps. Full stacks connect all for complete keg performance visibility.

Does KegChek do both keg tracking and pour tracking?

Yes - seamless keg tracking with optional pour integration, RFID/GPS, and lifecycle analytics to cut losses and boost ROI.

How accurate is pour tracking for inventory?

5-10% variance typical if logged consistently; excels at waste detection but misses keg logistics without tracking.

What's the cost of keg tracking software like KegChek?

Affordable mobile-first plans - no heavy hardware. Starts low, scales with fleet size for real ROI on lost keg recovery.

Final Thoughts

Understanding the difference between keg status monitoring and pour tracking isn’t just technical terminology - it’s the foundation of building an efficient draught operation.

If your goal is to know where your kegs are, you need tracking. If your goal is to know how your beer is being poured, you need pour analytics. And if you want a complete picture of performance, you need both working together.

The breweries that recognize this distinction today are the ones building the smartest draught ecosystems tomorrow.